- Home

- About Us

- Products

Air Pollution Control System

Industrial Blower

Indoor Air Quality (IAQ) Solution

Ventilation System

Filter Accessories

Steel Fabrication

- Applications

- Service

- Gallery

- Contact us

- Home

- About Us

- Products

Air Pollution Control System

Industrial Blower

Indoor Air Quality (IAQ) Solution

Ventilation System

Filter Accessories

Steel Fabrication

- Applications

- Service

- Gallery

- Contact us

- Home

- Products

- Filter Accessories

- Premium Filter Bags

Filter Bags

Premium Filter Bags for Comprehensive Applications

At HANZA ENVIROTEC, we stand at the zenith of innovation and quality in the UAE and across the Middle East. Recognized as leading suppliers, we specialize in crafting state-of-the-art filter bags tailored to cater to a myriad of applications, be it gas, liquid, or dust filtration.

Our filter bags aren’t just products; they are solutions. Born out of a detailed understanding of our clients’ needs, each filter bag is meticulously designed, ensuring optimized performance for every distinct process.

Our vertical integration, beginning from judicious raw material selection, ensures complete traceability. Stringent quality controls at every production stage testify to our commitment to excellence.

- Top Cuff: Precision in sizing the top cuff is crucial for maintaining stability and airtight sealing. At HANZA, we offer bespoke solutions catering to any configuration our clients necessitate.

- Tubular Design: Crafted on state-of-the-art automated lines, our tubular structure boasts triple continuous stitching or heat sealing. The choice of technique aligns with the specific properties of polymers used.

- Bottom Construction: Recognizing the stress the bottom endures during operations, we ensure its design maximizes resistance and efficiency over extended periods.

- PTFE Taping: To amplify the bag’s durability and filtering efficiency, we seal seams and tubular details with specialized PTFE taping, safeguarding them from wear.

- Woven Fabric Filters:

- Typically made of woven cotton, polyester, or other synthetic materials.

- Suitable for applications where the particulate is larger and not abrasive.

- Needled Felt Filters:

- Comprised of polyester, polypropylene, acrylic, aramid (Nomex), PPS (Ryton), PTFE (Teflon), fiberglass, or other synthetic fibers.

- Ideal for capturing fine particles due to their depth-loading properties.

- Membrane Filters:

- Feature a microporous membrane, often PTFE, laminated to a sturdy base material, typically a needled felt.

- Offer high filtration efficiencies, capturing extremely fine particulates.

- Fiberglass Filters:

- Comprised of woven or felted fiberglass material.

- Resistant to high temperatures, making them suitable for applications with hot gases.

- PTFE (Polytetrafluoroethylene) Filters:

- Often known by the brand name Teflon, these filters are inherently resistant to chemicals and offer excellent temperature resistance.

- Aramid (often called Nomex) Filters:

- Excellent in high-temperature applications.

- Resistant to many chemicals but can hydrolyze in moist conditions.

- Polyphenylene Sulfide (PPS or Ryton) Filters:

- Resistant to both chemicals and temperatures.

- Suitable for applications with acid gases.

- Polypropylene Filters:

- Best suited for applications with wet acidic or alkaline conditions.

- Resists most acids, alkalis, and solvents.

- Acrylic Filters:

- Effective in moderate temperature applications.

- Good hydrolytic, acid, and alkali resistance.

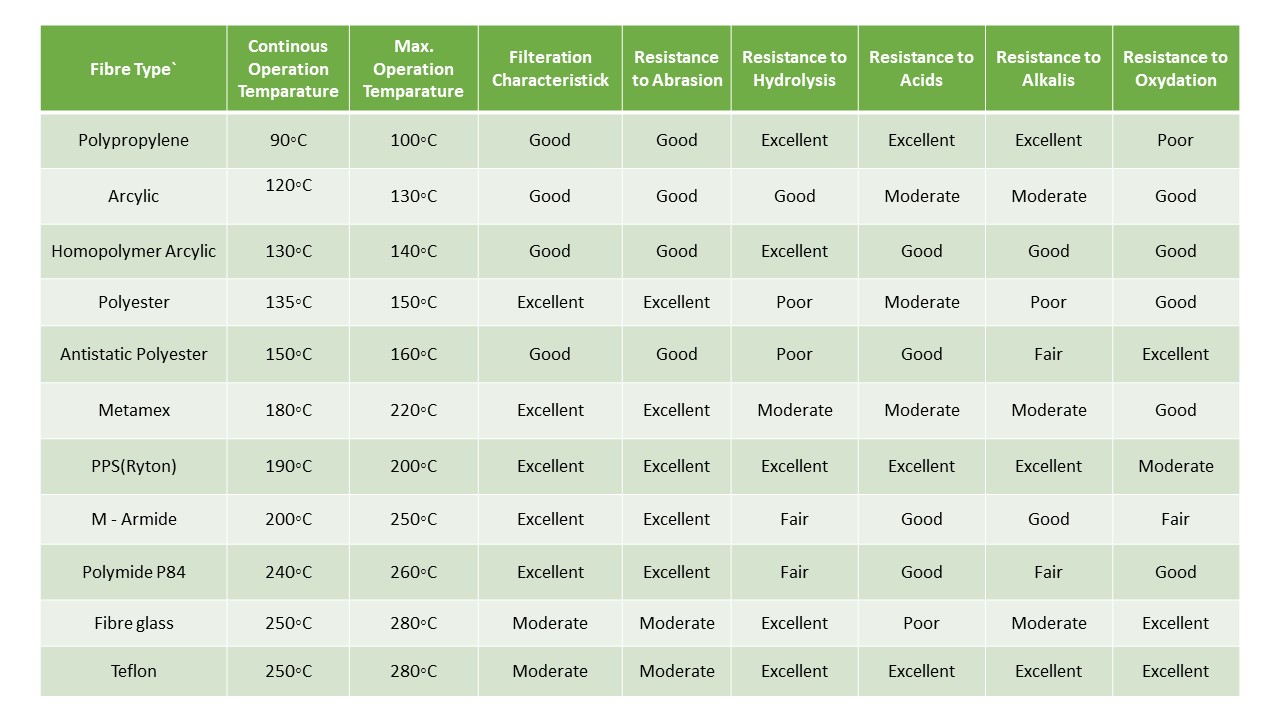

- Temperature: Some media, like fiberglass and PTFE, are suitable for high-temperature applications, while others, like polypropylene, are used in lower temperature conditions.

- Chemical Resistance: Certain gases can react or degrade specific media. For example, Aramid (Nomex) is sensitive to moisture in acidic conditions.

- Particulate Size: Fine particulates require media with depth-loading properties, such as needled felts, to capture them effectively.

- Air-to-Cloth Ratio: Determines how fast the air will flow through the filter media. Different media have different permeabilities affecting this ratio.

- Moisture Content: Some filter media can handle moisture better than others.

- Abrasion: If the dust or particulate is abrasive, a robust and durable filter media is needed.

- Disposal: Some media are more environmentally friendly or easier to dispose of than others.

It’s crucial to select the right filter bag media for the specific application to ensure optimal filtration, reduced downtime, and extended filter life. Proper maintenance and periodic replacement are also essential for maintaining peak performance.

Why HANZA ENVIROTEC?

Being in the heart of the Middle East, we understand the region’s unique demands. Our legacy is built on a foundation of unparalleled quality, relentless innovation, and unwavering commitment to customer satisfaction. For filter bags that truly resonate with excellence, trust HANZA ENVIROTEC.

For solutions that redefine filtration, choose HANZA ENVIROTEC.

“Hanza Environment Technology Factory” is located in the heart of the industrial city of ( ICAD 2 ) Abu Dhabi, the factory is specialized in the manufacturing of environmental related products and it highly concentrates on the Air Filtration equipments.

THE COMPANY

Services

Contact

- (+971) 2 4454 054

- info@hanza-envirotec.com

- P.O.Box: 402, Abu Dhabi, UAE

- Mon to Sat - 08:00 to 04:30