- Home

- About Us

- Products

Air Pollution Control System

Industrial Blower

Indoor Air Quality (IAQ) Solution

Ventilation System

Filter Accessories

Steel Fabrication

- Applications

- Service

- Gallery

- Contact us

- Home

- About Us

- Products

Air Pollution Control System

Industrial Blower

Indoor Air Quality (IAQ) Solution

Ventilation System

Filter Accessories

Steel Fabrication

- Applications

- Service

- Gallery

- Contact us

- Home

- Products

- Air Pollution Control System

- Scrubbers (Wet and Dry)

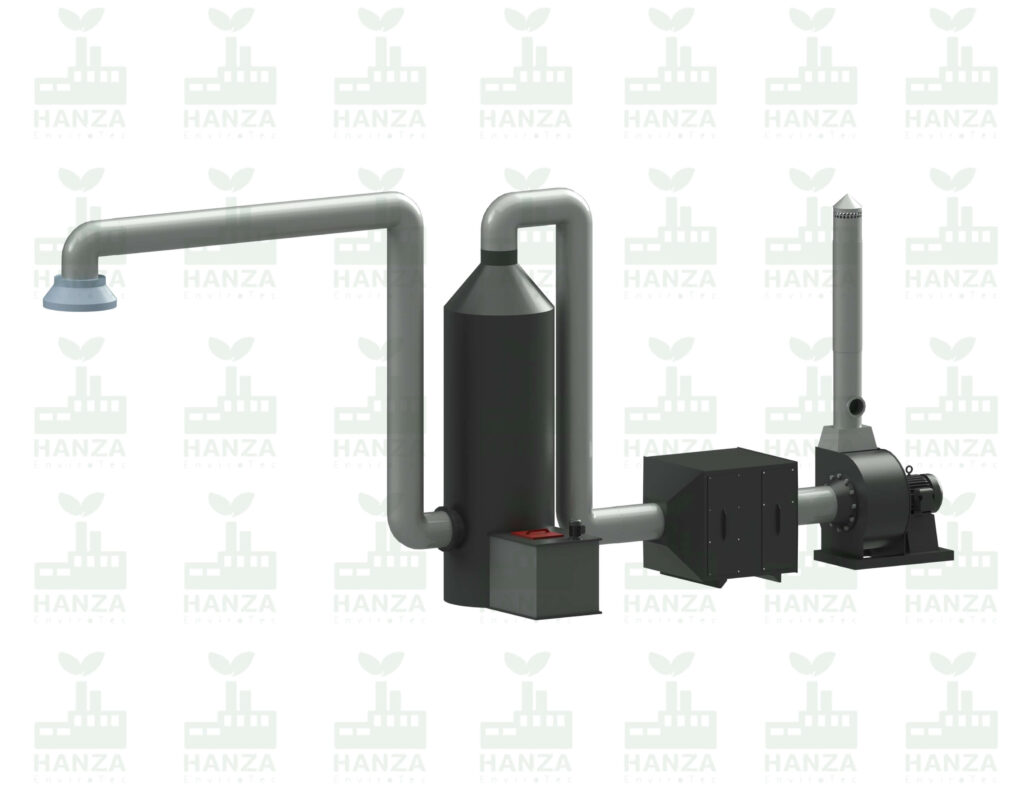

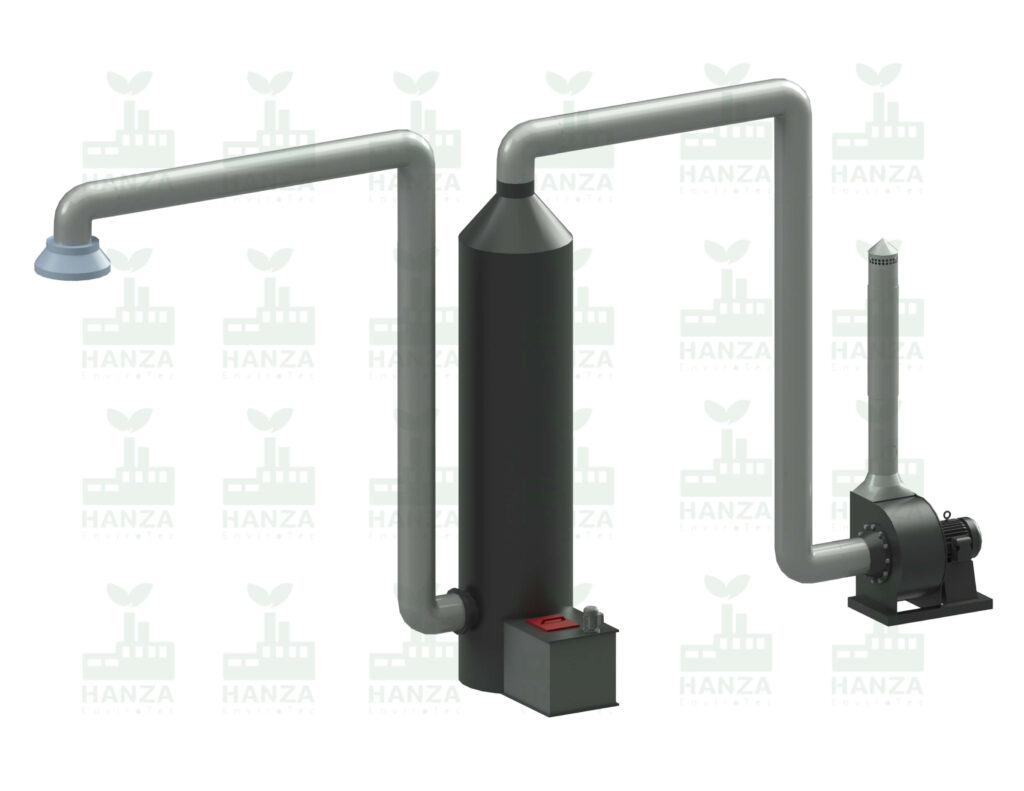

Wet Scrubber System

In environments where sparking dust poses risks of combustion or explosions, wet scrubbers serve as the preferred dust collection method. These systems primarily use water to neutralize or “scrub” particles. While compact compared to dry fabric dust collectors, wet scrubbers necessitate consideration for corrosion and potential secondary water pollution.

Function: Air laden with dust traverses a horizontal chamber meeting submerged baffle plates that wet the dust. Once wetted the dust descends to a hopper while air ascends finally being extracted through terminal filters. An ID exhauster is positioned at the final outlet for effective air removal.

Design: HANZA ENVIROTEC’s Packed Bed Scrubber is tailored for each application, ensuring cost-effective and efficient gas cleansing. Unique packing media provides vast surface area for maximum gas and liquid interaction.

Efficiency: The design ensures optimal scrubbing efficiency, compactness and minimal pressure drops. Multiple configurations and options are available to suit diverse applications.

Mechanism: HANZA ENVIROTEC’s design cleans air using centrifugal force combined with extensive water and dust interaction. Dust separation occurs via a water curtain, created by airflow through a submerged stationary impeller. The centrifugal force ensures dust particles infiltrate the water film and become entrapped.

Water Usage: Water droplets in the cleaned air are eradicated by wide-space chevron eliminators or curved de-entrainment baffles. The continually used water in the reservoir requires no pumps or nozzles, thanks to the airflow-driven water curtain.

HANZA ENVIROTEC Venturi Scrubber

Design: Features a “Wet Approach” venturi combined with a liquid entrainment separator. Dust-filled gases undergo immediate interaction with a swirling scrubbing liquid. At the venturi core, they collide, converting the liquid into droplets that capture dust.

Operation: The gas and liquid mixture progresses through a flooded elbow, enters an entrainment separator, and undergoes centrifugal action to cleanse the gas stream. Large diameter separators utilize a mist eliminator baffle for liquid separation.

“Hanza Environment Technology Factory” is located in the heart of the industrial city of ( ICAD 2 ) Abu Dhabi, the factory is specialized in the manufacturing of environmental related products and it highly concentrates on the Air Filtration equipments.

THE COMPANY

Services

Contact

- (+971) 2 4454 054

- info@hanza-envirotec.com

- P.O.Box: 402, Abu Dhabi, UAE

- Mon to Sat - 08:00 to 04:30