- Home

- About Us

- Products

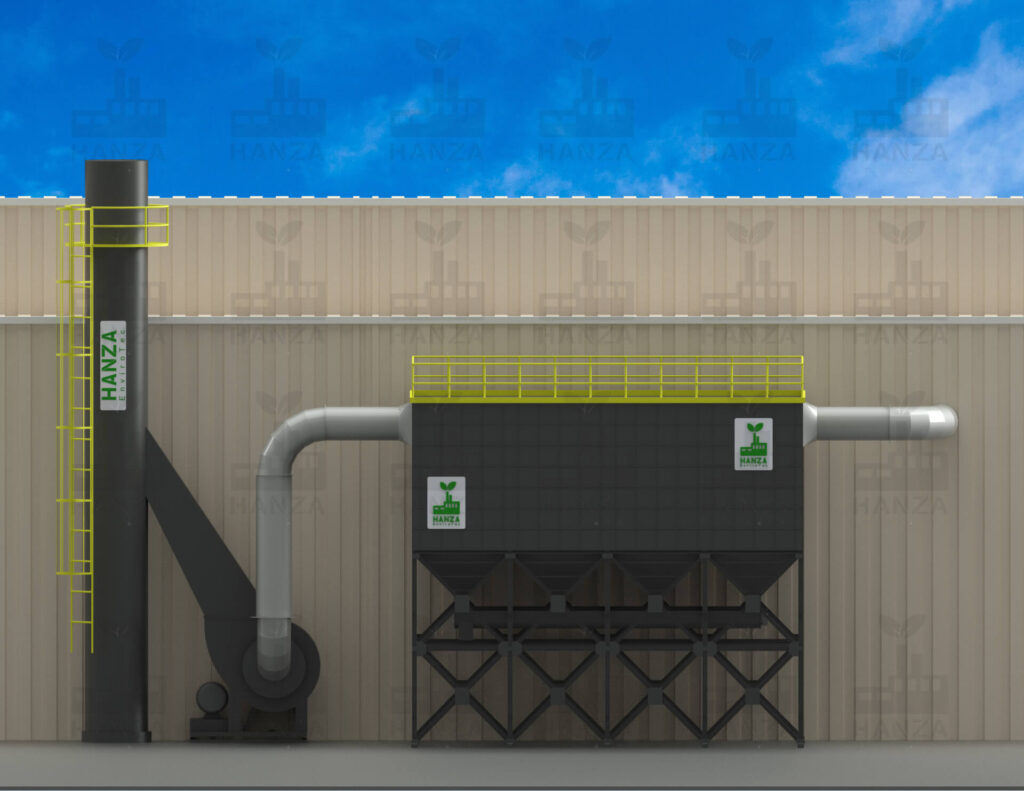

Air Pollution Control System

Industrial Blower

Indoor Air Quality (IAQ) Solution

Ventilation System

Filter Accessories

Steel Fabrication

- Applications

- Service

- Gallery

- Contact us

- Home

- About Us

- Products

Air Pollution Control System

Industrial Blower

Indoor Air Quality (IAQ) Solution

Ventilation System

Filter Accessories

Steel Fabrication

- Applications

- Service

- Gallery

- Contact us

Services

Filtration Equipment Service

HANZA ENVIROTEC

Innovating Clean Air Solutions

At HANZA ENVIROTEC, we don’t just manufacture cutting-edge jet pulse filters and dust collectors; we ensure they deliver enduring value throughout their lifecycle. We recognize the critical importance of operational efficiency, safety, and sustainability in every industry we serve. Thus, we are proud to expand our commitment to a holistic service model.

With vast experience under our belt, we’ve evolved into a full-fledged service provider for bag-house filters and cartridge filters. Our dedicated service teams are equipped to handle everything from routine maintenance to complex refurbishments, ensuring your systems operate at their peak, always.

Ensuring the longevity and optimal performance of your equipment is our utmost priority. Our extensive spare parts inventory means that we’re always ready to supply you with the exact components you need, minimizing downtime and maximizing operational continuity.

Expertise: Decades of experience in the design, manufacture, and service of filtration systems.

Reliability: A trustworthy partner for maintenance and refurbishment solutions.

Quality: Only the best and most compatible spare parts for your equipment.

Timely Service: We understand the cost of downtime and strive to provide prompt and effective services.

HANZA ENVIROTEC remains at the forefront of environmental technology solutions. By entrusting your equipment’s service and maintenance to us, you’re ensuring a future of clean, safe, and efficient operations.

Blower Refurbishment / Fan Repair & Service

HANZA ENVIROTEC

Driving Airflow Excellence

At HANZA ENVIROTEC, we specialize in the design and manufacture of high-quality centrifugal fans and blowers. But our commitment to airflow solutions goes beyond just manufacturing. We believe in ensuring the longevity and efficiency of every product we craft.

Our expertise isn’t limited to creating centrifugal fans and blowers. We’ve extended our services to cater to the diverse maintenance needs of our clientele. Whether it’s routine checks, detailed refurbishments, or performance audits, our skilled team is equipped to handle the intricacies of fan and blower systems.

Downtime can impact productivity, and we understand the pivotal role spare parts play in reducing such instances. We maintain a comprehensive inventory of high-grade components, ensuring you always have access to genuine and timely spare parts for your equipment.

Experience: A rich legacy in designing, manufacturing, and servicing centrifugal fans and blowers.

Quality: Superior craftsmanship combined with top-of-the-line spare parts ensures your equipment’s best performance.

Prompt Services: Recognizing the essence of time, our services are not only effective but also timely.

Trust: As a renowned name in the industry, our commitment is to guarantee your equipment’s optimal functionality at all times.

At HANZA ENVIROTEC, we are more than just manufacturers; we are your dedicated partners in ensuring consistent, efficient, and reliable airflow solutions.

Dynamic Balancing

HANZA ENVIROTEC

Precision in Every Rotation

At HANZA ENVIROTEC, we are not only recognized for our superior manufacturing of fan impellers but also for the precision and care with which we ensure their performance. In the world of rotating equipment, the smallest imbalance can lead to inefficiencies, increased wear, and even potential equipment failure.

Our commitment to excellence goes beyond mere manufacturing. We offer specialized dynamic balancing services, tailored for fan impellers and shafts. Using advanced dynamic balancing machines, we methodically measure the dynamic forces generated by a rotating impeller. By mounting the impeller on our specialized equipment, and spinning it at high speeds, we identify and correct any imbalances to an unparalleled degree of precision.

Importantly, our dynamic balancing services are executed in strict accordance with International Standard ISO 1940/G 6:3. This adherence ensures that our clients receive a level of quality and precision that meets global benchmarks.

Precision: Adherence to ISO 1940/G 6:3 guarantees the highest level of balancing accuracy.

Expertise: Years of industry experience in both manufacturing and maintenance.

State-of-the-Art Technology: Our dynamic balancing machines are the epitome of modern engineering and accuracy.

Commitment: We’re dedicated to ensuring that every fan impeller operates at its optimal efficiency and reliability.

At HANZA ENVIROTEC, precision isn’t just a goal; it’s a promise. Entrust us with your fan impellers, and experience the difference that globally recognized excellence brings.

Plant Machinery/Equipment's Service

HANZA ENVIROTEC

Ensuring Operational Excellence in Every Detail

At HANZA ENVIROTEC, our dedication goes beyond creating superior machinery and equipment solutions. We understand that for our clientele, maintaining optimal operational efficiency is paramount. That’s why we have expanded our horizons to offer unparalleled service and maintenance for plant machinery and equipment.

Plant machinery and equipment, being the heart of many industrial operations, require regular attention to ensure they perform at their peak. Our skilled team, backed by years of experience, is equipped to handle a wide range of service and maintenance tasks. Whether it’s a routine check-up, intricate refurbishments, or performance optimizations, we’ve got you covered.

Expertise: Our team’s deep knowledge spans across various types of plant machinery and equipment.

Quality Assurance: We aim to restore and maintain machinery to its original performance standards or better.

Prompt Response: Recognizing the costs associated with downtime, we prioritize efficient and swift service delivery.

Tailored Solutions: Understanding that each machinery and its usage is unique, we provide customized maintenance plans to suit your specific needs.

Choose HANZA ENVIROTECas your trusted partner for plant machinery and equipment services, and ensure a future of uninterrupted, efficient operations.

Hydro Washing

HANZA ENVIROTEC

Precision, Purity, Performance

At HANZA ENVIROTEC, our commitment to industrial excellence doesn’t stop at creating and maintaining equipment. We understand that cleanliness and purity play an essential role in ensuring optimal performance, longevity, and safety of plant machinery and structures. This realization has driven us to specialize in the domain of Hydro Washing.

Plant Equipment & Machinery: Enhancing performance and extending the life of machinery.

Steel Structures: Ensuring structural integrity, appearance, and prolonged lifespan.

Industrial Sites**: Effective cleaning without the use of harmful chemicals.

Efficiency: Quick and thorough cleaning that minimizes downtime.

Eco-friendly: Uses only water, avoiding the introduction of chemical contaminants into the environment.

Expertise: Our trained professionals have extensive experience ensuring safe and effective washing.

Versatility: Suitable for a wide range of industrial applications.

At HANZA ENVIROTEC, we believe in comprehensive care for your industrial assets. Trust in our Hydro Washing expertise and ensure that your machinery and structures not only look their best but also perform at their peak.

Abrasive Blasting & Painting

HANZA ENVIROTEC

Restoration, Renovation, Revitalization

At HANZA ENVIROTEC, we believe that excellence in industrial maintenance encompasses both deep cleansing and aesthetic restoration. With this philosophy at our core, we proudly offer comprehensive Abrasive Blasting and Painting services, designed to rejuvenate plant equipment, machinery, and steel structures.

The challenges posed by accumulated layers of dirt, corrosion, and old paint require a holistic approach. Our Abrasive Blasting services strip away these imperfections, laying the groundwork for a fresh, protective, and visually appealing coat of paint.

Plant Equipment & Machinery: Enhancing operation by not only cleansing but also adding a protective layer against future wear and tear.

Steel Structures: Reinvigorating the aesthetic appeal while ensuring structural durability through protective coatings.

Industrial Facilities: Creating a cleaner, more vibrant environment that aligns with professional and safety standards.

Comprehensive Care: From meticulous blasting to precise painting, we handle every step with expertise.

Safety Commitment: All procedures adhere to strict safety standards, safeguarding assets and personnel.

Experienced Craftsmanship: Our seasoned team brings together skill, dedication, and the best equipment in the field.

Versatile Solutions: We tackle projects of all sizes, delivering consistent quality across the board.

With HANZA ENVIROTEC at your side, breathe new life into your industrial assets. We cleanse, coat, and care, ensuring that every piece not only functions seamlessly but also looks its absolute best.

Baghouse filters are used in various industrial applications to capture dust, particles, and pollutants from air or gas streams. Over time, these filters can become clogged or damaged, reducing their effectiveness.

Baghouse filter refurbishment involves the cleaning, repair, and replacement of filter bags and related components within a baghouse system. This service helps restore the filter’s efficiency and extend its lifespan, reducing maintenance costs and improving air quality.

Baghouse filters are used in various industrial applications to capture dust, particles, and pollutants from air or gas streams. Over time, these filters can become clogged or damaged, reducing their effectiveness.

Baghouse filter refurbishment involves the cleaning, repair, and replacement of filter bags and related components within a baghouse system. This service helps restore the filter’s efficiency and extend its lifespan, reducing maintenance costs and improving air quality.

Baghouse filters are used in various industrial applications to capture dust, particles, and pollutants from air or gas streams. Over time, these filters can become clogged or damaged, reducing their effectiveness.

Baghouse filter refurbishment involves the cleaning, repair, and replacement of filter bags and related components within a baghouse system. This service helps restore the filter’s efficiency and extend its lifespan, reducing maintenance costs and improving air quality.

Baghouse filters are used in various industrial applications to capture dust, particles, and pollutants from air or gas streams. Over time, these filters can become clogged or damaged, reducing their effectiveness.

Baghouse filter refurbishment involves the cleaning, repair, and replacement of filter bags and related components within a baghouse system. This service helps restore the filter’s efficiency and extend its lifespan, reducing maintenance costs and improving air quality.

Baghouse filters are used in various industrial applications to capture dust, particles, and pollutants from air or gas streams. Over time, these filters can become clogged or damaged, reducing their effectiveness.

Baghouse filter refurbishment involves the cleaning, repair, and replacement of filter bags and related components within a baghouse system. This service helps restore the filter’s efficiency and extend its lifespan, reducing maintenance costs and improving air quality.

“Hanza Environment Technology Factory” is located in the heart of the industrial city of ( ICAD 2 ) Abu Dhabi, the factory is specialized in the manufacturing of environmental related products and it highly concentrates on the Air Filtration equipments.

THE COMPANY

Services

Contact

- (+971) 2 4454 054

- info@hanza-envirotec.com

- P.O.Box: 402, Abu Dhabi, UAE

- Mon to Sat - 08:00 to 04:30